TZM Alloys

Description:

TZM alloy is a high strength molybdenum based alloy containing titanium, zirconium and carbon. Comparing to pure molybdenum products, it has better creep resistance, higher recrystallization temperature and better welding properties. Concerning the tensile strength at 1100℃, TZM alloy is about twice as much as that of unalloyed molybdenum.

Application:

1. TZM alloy is widely used in the aerospace, aviation and other industries;

2. It could be used as nozzle material, valve body, gas piping materials as well as tubes in the gate material;

3. TZM alloy also can be used for producing die casting molds, extrusion dies, high temperature furnace heating element and heat shield, etc.

Features:

1. It of high density above 10.16 g/cc at 20°C;

2. The recrystallization temperature is as high as 1425℃ to 1595°C;

3. Its stress-relief temperature at 1095℃ to 1260°C can maintain for 1 hour;

4. The liquidus temperature of TZM alloy is 2620°C;

5. Chemical Composition of TZM alloy: Mo + 0.40~0.55%Ti + 0.06~0.12%Zr + 0.01~0.04% C.

Parameters of TZM Alloy:

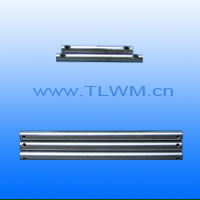

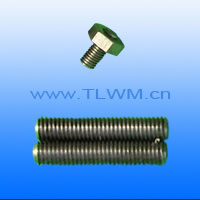

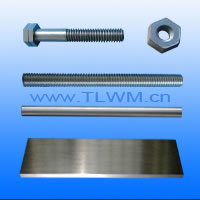

LTWM could offer all kinds of TZM alloys in rods, plates and fabricated parts according to customers' drawings.

Packing and Shipping:

We deliver TZM alloys in plywood cases by ocean shipping or air transportation.

- TZC AlloysTZC alloy is one of main classes of commercial molybdenum-base alloys. It contains molybdenum mainly as well as 1.2% titanium, 0.3% zirconium and 0.1% carbon. TZC alloy is an improvement of TZM alloy. By using powder metallurgy and vacuum melting method, LTWM provides superior TZC alloys with excellent ...