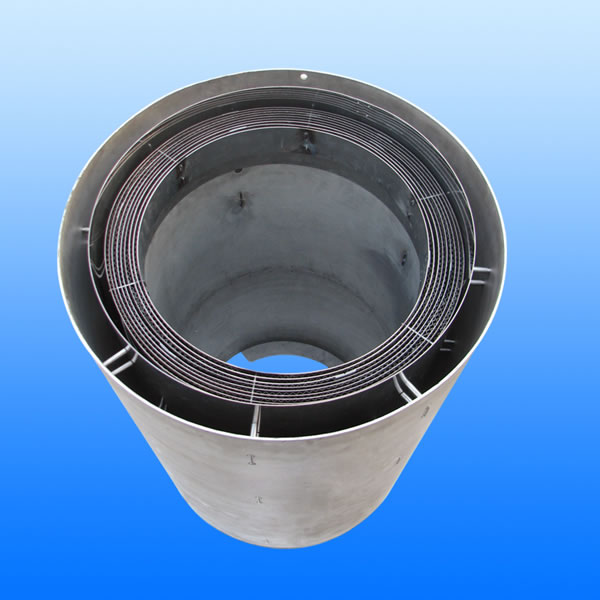

Tungsten and Molybdenum Heat Shield

Description:

As a kind of auxiliary tool, tungsten and molybdenum heat shields are designed to stabilize temperature of the growth furnace and to prevent the outside temperature from impacting melt in the crucible. Also, they can be applied in optical instruments.

Features:

1. The purities of both tungsten and molybdenum heat shield are as high as 99.95%;

2. Their densities of are 19.3g/cm3 and 10.2g/cm3 respectively;

3. Their vapor pressure at 2100℃ are about 10-6 Pa and 10-2 Pa respectively;

4. The plastic brittle transition temperature of tungsten heat shield is within the ranges of 200℃ to 400℃,while molybdenum heat shield is between 20℃ and 200℃;

5. The fully recrystallization temperature of tungsten and molybdenum heat shield are about 1350℃ and 1050℃ respectively;

6. Both tungsten and molybdenum heat shield are of high oxidation resistance. Tungsten heat shield oxidizes sharply at the temperature above 500℃;while molybdenum heat shield oxidizes at 400℃.They are easily being oxidized only when the relative humidity reaches 60%. So they should be applied under dry environment.

Parameters of Tungsten and Molybdenum Heat Shield:

| Parameters | Tungsten Heat Shield | Molybdenum Heat Shield |

| Thickness (mm) | 0.2, 0.3, 0.5, 1.0, 2.0 | |

| Thickness Tolerance | within 10% of the plate thickness | |

| Biggest Side Screen Cylinder Diameter (mm) | Φ400 | Φ800 |

| Biggest Side Screen Cylinder Height (mm) | 600 | 700 |

| Biggest Cover Screen Diameter(mm) | Φ700 | Φ600 |

1. Super large size tungsten and molybdenum heat shields could be manufactured by joining several plates together to meet specific needs;

2. We can also produce heat shields according to customers' requirements.

Notice:

1. Tungsten and molybdenum heat shields are fragile materials. Special care must be taken during the operation to ensure them (especially tungsten heat shield) safe and sound;

2. The relative humidity of the working environment should be no more than 60%; otherwise heat shields are easily catch oxidation;

3. After first usage, tungsten and molybdenum heat shields are more brittle after recrystallation and need to handle with more care;

4. Tungsten and molybdenum heat shields oxidize sharply under the high temperature environment. The vacuum degree should be no more than 10-3Pa;

5. The evaporation rate of molybdenum outweighs that of tungsten. Tungsten heat shield is recommended to applied in the hot zone over 1800℃.

Packing and Shipping:

We deliver pure tungsten and molybdenum heat shields in plywood cases by ocean shipping or air transportation.

- Tungsten Support RodsTungsten support rod, with high density, high melting point, excellent hardness, high tensile strength, high temperature resistance, low vapor pressure as well as superior wearing resistance, is gradually standout among the various swaging rod making materials. As a component of heating element, tungsten support post is ...