Description:

As the hardest oxide crystal, sapphire (Al2O3) outgrow form hot zone has a combination of good optical and physical properties, which makes it the best choice for a variety of demanding applications. It has good thermal properties, excellent electrical and dielectric properties as well as good chemical erosion resistance. Sapphire outgrow form hot zone could maintain its strength even at very high temperature. These properties encourage sapphire widely used as the LED substrate in aggressive environments where reliability, optical transmission and strength are required. With the tremendous growth of the LED, TV and LED lighting market, there is an increasingly strong demand for sapphire.

Due to the high temperature resistance, low pollution and other good characteristics of hot zone in sapphire grower, tungsten and molybdenum are used to manufacture the hot zone components in sapphire growth furnace including: tungsten crucibles, molybdenum crucibles, heaters, tungsten tubes, heat insulation screens, supports, covers etc. Our company can supply excellent quality hot zones for sapphire growth furnace according to customers’ requirements. LTWM offers 30Kg,60Kg,85Kg,120Kg full set hot zone in the sapphire grower and all the tungsten, molybdenum components used in hot zone.

Application of Sapphire:

1. Sapphire outgrow from hot zone has been widely used in infrared military equipment, satellite space technology and window material of high strength laser;

2. Also it gradually becomes ideal substrate materials for GaN semiconductor light emitting diode (LED).

Features of Sapphire:

1. Sapphire outgrow from hot zone has excellent optical performance, high mechanical strength and stable chemical performance;

2. It can be applied under very bad condition at temperature close to 2000 ℃.

The Common Methods of Getting Sapphire from Hot Zone:

1. Czochralski Method: Pull sapphire from the melt;

2. Kyropoulos Method: Dip and turn;

3. EFG Method (Edge Defined Film-fed Growth): Pull sapphire through die;

4. Heat Exchange Method (HEM Method);

5. Vertical Horizontal Gradient Freezing (VHGF): A technology from Korea Sapphire Technology Company;

6. ES2-GSA Method: A technology from USA Rubicon Technology Inc.

Packing and Shipping:

We deliver hot zones for sapphire growth furnace in plywood cases by ocean shipping or air transportation.

Bottom Shield Bottom Shield |

Current Lead Shield Current Lead Shield |

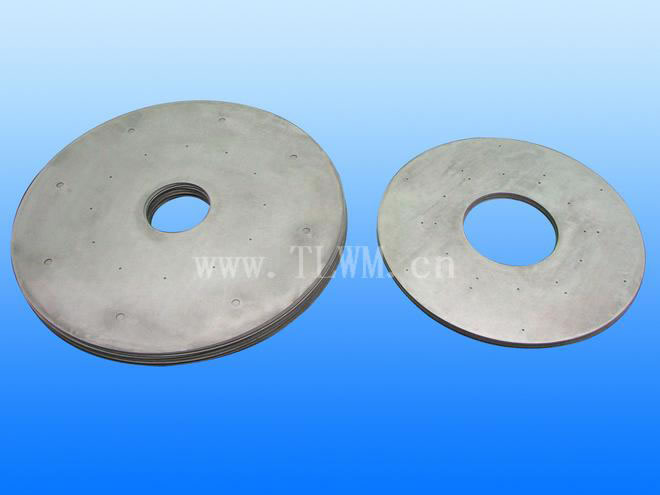

Heat Insulation Screen Heat Insulation Screen |

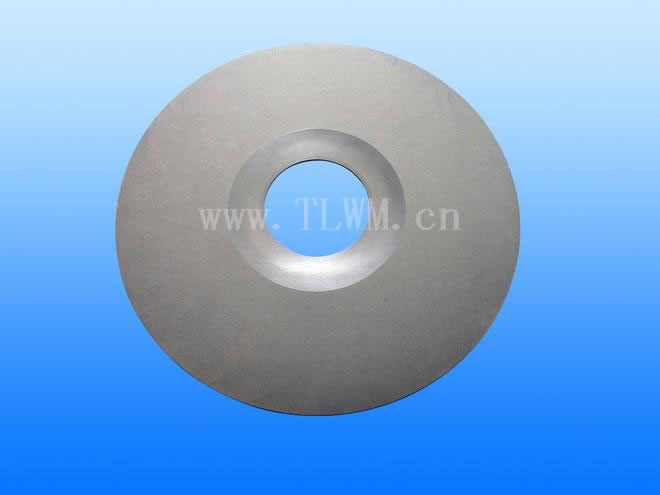

Top Shield Top Shield |

Tungsten Crucible Tungsten Crucible |